Eco-Friendly Ultrasonic Treatment System Controls Algae in Power Plant Settling Pond

|

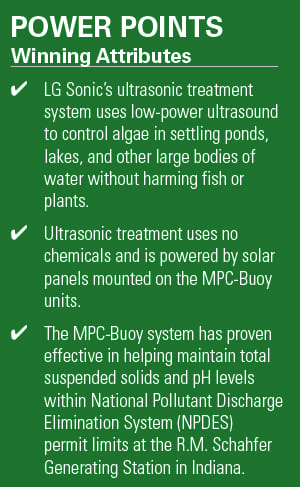

Water treatment professionals often turn to chemicals to control algae in power plant settling ponds. While this can be effective, environmentally friendly ultrasonic technology may do a better job at a fraction of the cost—and with no harm to fish or plants.

The National Pollutant Discharge Elimination System (NPDES) permit program was created in 1972 by the Clean Water Act. The NPDES helps address water pollution by regulating point sources that discharge pollutants to waters of the U.S.

Effluent limitations serve as the primary mechanism in NPDES permits for controlling discharges of pollutants to receiving waters. Effluent limitations guidelines and standards are established by the U.S. Environmental Protection Agency for different non-municipal categories. These guidelines are developed based on the degree of pollutant reduction attainable by an industrial category through the application of pollutant control technologies.

It can be difficult for power plants to comply with NPDES permit limits. For example, Northern Indiana Public Service Co.’s (NIPSCO’s) Rollin M. Schahfer Generating Station, located in Jasper County near Wheatfield, Indiana, operates four coal-fired units with a combined capacity of about 1,943 MW. The facility takes its cooling water from the Kankakee River. Before being returned to the river, the water is discharged to a final settling basin, which has a surface area of about 194 acres and an average depth of about 10.7 ft. The water must meet NPDES permit limits when being discharged back to the river.

Among the requirements are that the concentration of total suspended solids (TSS) must be less than 30 parts per million (ppm) on a daily basis and less than 15 ppm on a monthly average, and the water pH must be less than 9. Settling ponds are commonly rich in nutrients, and the temperature of water in Schahfer’s basin is warmer than river water, having absorbed heat in condensers while passing through the plant. This causes algae to grow at a relatively fast rate, and algal blooms have an adverse effect on TSS and pH.

NIPSCO used algaecides for years in its cooling water program in order to meet the NPDES limits at the final settling basin. However, algaecides can be expensive and options were limited because algaecides could not be directly added to the basin due to the pond discharge going back to the river. The company tested other options to lower TSS levels, but results were inconsistent and filters from TSS samples were often green. Filtration of the pond discharge was considered, but it was not really an economical option.

Ultrasonic Treatment

Finally, NIPSCO came across LG Sonic, a company that calls itself a “leader in sustainable algae management.” NIPSCO worked directly with the company to develop an ultrasonic solution, utilizing LG Sonic’s MPC-Buoy technology. MPC-Buoy is a floating solar-powered system that combines real-time water quality monitoring and ultrasonic sound waves to effectively control algae.

“Controlling algae with low-power ultrasound is a well-established technology that has been in existence for many years. It is an environmentally friendly technology that is harmless to fish and plants,” Lisa Brand, CTO for LG Sonic, told POWER.

Ultrasound can be used in both fresh water surfaces, such as lakes, drinking water reservoirs, and irrigation basins, as well as in maritime environments. By controlling the algae, it is possible to improve the clarity of the water, and reduce TSS and pH.

The Science Behind the Technology

To understand how LG Sonic’s MPC-Buoy system targets algae, it is helpful to understand algae’s growing mechanism. All single-celled planktonic algae use some form of buoancy regulation to remain at the surface of the water where most light is available, Brand explained. During the day, algae are photosynthesizing in the top layer, using carbon dioxide and dissolved nutrients from the surrounding water to produce oxygen and polysaccharides.

To control algae, the LG Sonic system transmits specific ultrasonic waves in the water. The sound waves can spread through the water column for hundreds of meters. The ultrasound waves create a sound layer in the top layer of the water, which affects the buoyancy regulation of the algae, fixing them in the water column. The algae cells sink to the deeper and darker layers of the water column where they are not able to photosynthesize, and they eventually die due to a lack of sunlight.

Specific frequency programs are used, based on the type of algae to be controlled. Due to the adaptability of algae during seasons within a lake or other large body of water, the ability to change these ultrasonic frequencies is important for long-term success.

Brand said ultrasonic algae control does not significantly alter the basic level of algae present in a lake or reservoir. However, due to the direct effect of the ultrasound on the vertical distribution of algae in the water column, the ultrasound directly influences the capability of an algal species to form a bloom. In general, these blooms can be reduced by 70% to 90% in concentration, compared to a non-treated body of water.

MPC-Buoy

LG Sonic’s MPC-Buoy makes use of specific and low-power ultrasound (5–20 W per transmitter). As Brand noted, multiple studies have proven low-power ultrasound to be harmless to fish and plants. However, there are other ultrasonic methods too. One less-eco-friendly type produces cavitation using high-power ultrasound. Cavitation is a phenomenon in which high-power ultrasound causes the formation of bubbles that implode upon themselves causing intense heat and pressure, which can destroy cells, and has been known to have a harmful impact on the ecosystem. Furthermore, due to the high power requirements for cavitation-style systems, it is impractical to use the method for treatment of lakes or any large water surface.

“LG Sonic provides continuous support from their engineers to analyze how to best place the units in the reservoirs and estimate at what rate to move away from chemical use when treating algae with ultrasound, and finally, advise on general reservoir management as LG Sonic monitors and treats water bodies across the globe,” Brand said.

For Schahfer’s settling pond, LG Sonic designed a setup with two MPC-Buoy Pro units and three MPC-Buoy Lite units (Figure 1). Pro units include ultrasound transmitters and water quality monitoring sensors customizable to users’ needs. Lite units only include ultrasound transmitters—no monitoring sensors. The Lite units receive ultrasonic treatment instructions from the Pro units.

|

|

1. The MPC-Buoy system installed at the R.M. Schahfer Generating Station uses solar photovoltaic cells to power ultrasound transmitters to control algae. Courtesy: LG Sonic |

The MPC-Buoy system does not require chemicals or other consumables. However, the sensors on the buoys need to be cleaned periodically. The cleaning is necessary about every two months and takes just a couple of hours to complete. Maintenance frequencies at other installations could vary, depending on the location, water quality, and weather.

Lessons Learned

The MPC-Buoy system was installed at the Schahfer site on April 1, 2019. The timing was important to NIPSCO because the company wanted to get units in place before algae gained a stronghold.

LG Sonic claims its units have a robust and intelligent design, which makes it easy for customers to install and maintain them. Installation and probe replacements are all straight forward, it said. According to LG Sonic, NIPSCO can easily complete installation of five buoys within one eight-hour shift. Removal and layup can also be done within eight hours.

NIPSCO discontinued most of the chemical treatment it was using on the settling pond at the Schahfer plant on the day the MPC-Buoy system was installed. That turned out to be a mistake, as the ultrasound had not yet begun to have an effect, and an algae bloom ensued. LG Sonic now recommends at least two weeks of ultrasound treatment and monitoring prior to making changes to previous treatment regimens.

“Lakes are a delicate ecosystem, and changes cannot happen overnight, so cooperation is necessary. NIPSCO was very accommodating in this process, as it was their top priority to not exceed the discharge limits,” said Brand.

In 2020, an issue arose due to an insufficiently anchored unit. It had been temporarily fixed in place with rope, but when a wind storm hit the site, the buoy broke free and was damaged when it hit a rocky shore. Fortunately, due to the modular design, only two transmitters and a pH sensor needed to be replaced—the rest was fine.

“Having a boat to quickly, easily, and safely access the buoys has proven to be essential for maneuvering and servicing the buoys at NIPSCO. It is best to have a boat that can hold three persons, allowing two persons to work over the side of the boat,” Brand said.

|

Favorable Results

“We were using both an algaecide [quaternary amine] and a UV-blocker at all our cooling towers. By the end of season [2019], we eliminated using the UV-blocker chemical and we reduced the algaecide by 25%,” Brian Snyder, senior chemical and environmental specialist with NIPSCO, told LG Sonic. “In 2020, we were able to further reduce use of algaecide to 33% of what we used before the [MPC-Buoy] installation.”

Snyder reported that the Schahfer site did have some days with higher than normal TSS in 2020, but it never exceeded the monthly average for compliance. He told POWER the TSS regularly stays below 6 ppm. During a webinar held on July 1, 2020, Snyder shared before and after images (2018 vs. 2019) of the reservoir, which clearly showed cleaner water in the basin. “We were very pleased with how well the first year of application went,” Snyder said in the webinar. ■

—Aaron Larson is POWER’s executive editor.